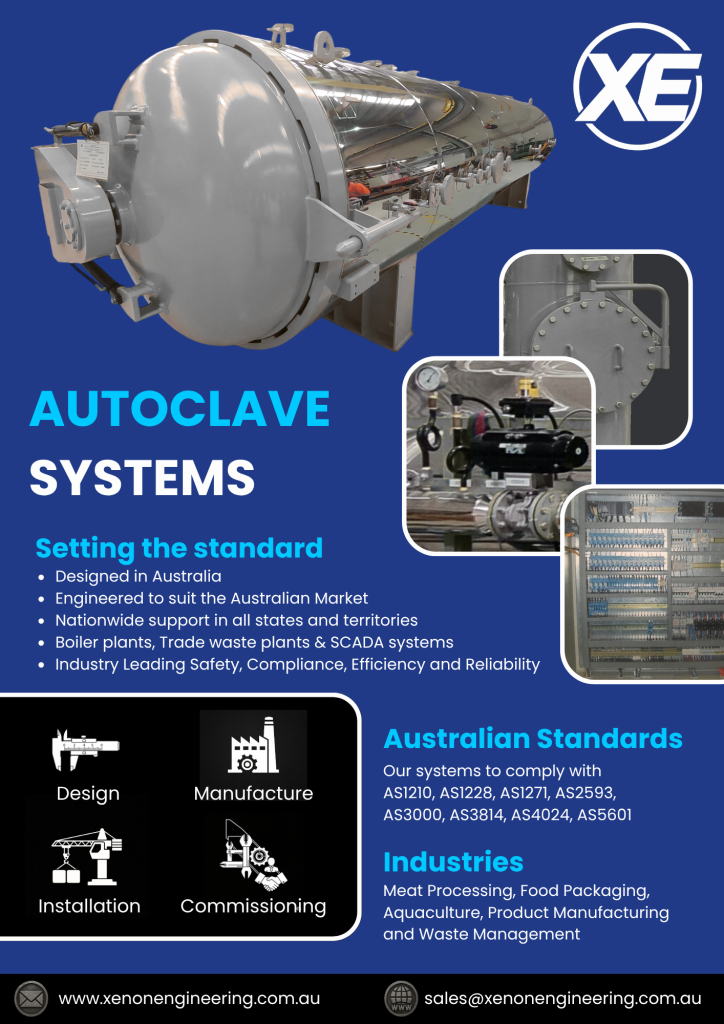

With over 30 years of experience, we are a premier Australian-based supplier specializing in the design, manufacturing, installation, and commissioning of high-performance thermal treatment systems. From industrial waste processing to precision material curing, our in-house engineering team delivers reliable, safe, and fully compliant turnkey solutions tailored to your unique application. Our capabilities include steam boilers, thermal oil heating systems, reactors, process tanks, and combustion systems integrated into complete thermal processing solutions.

Versatile Thermal Solutions Across Every Industry

Our expertise spans a wide array of specialized sectors, providing high-efficiency thermal treatment for:

Waste Management & Environmental Applications:

- Industrial and hazardous waste thermal treatment systems for volume reduction, sterilization, and decontamination.

- Waste-to-energy pre-treatment systems for safe, efficient energy recovery.

- Integration with steam boilers, thermal oil systems, and combustion systems for high-temperature processing.

Medical & Healthcare:

- Thermal processing of clinical, quarantine, and biohazard waste for hospitals, laboratories, and veterinary facilities.

- Secure sterilization of sharps and infectious materials using high-temperature reactors, thermal tanks, and combustion-assisted systems.

Pharmaceutical & Biotechnology:

- Controlled thermal treatment for vials, ampoules, active pharmaceutical ingredients (APIs), and laboratory-scale production.

- Thermal sterilization and drying of sensitive biotech materials, reagents, and culture media.

- Systems integrated with reactors, thermal oil heating, precision tanks, and combustion systems for controlled processing.

Food & Beverage:

- Advanced pasteurization, sterilization, and food waste processing systems for packaged and bulk food products.

- Thermal treatment solutions for beverage sterilization, bottling, and packaging.

- Steam boilers, thermal oil systems, and combustion-based heating used for precise temperature control in food processing.

Advanced Materials & Composites:

- High-precision curing of composite and synthetic materials, including Carbon Fibre, Fibreglass (FRP), Epoxy Resin, and Polyurethane.

- Thermal systems for rubber vulcanization and high-temperature polymer processing using thermal oil systems, reactors, and combustion systems.

Chemical Processing & Research Applications:

- High-temperature, high-pressure systems for chemical reactions, solvent recovery, and process sterilization.

- Scalable pilot plant thermal treatment solutions for R&D and laboratory applications.

- Reactors, tanks, thermal oil heating, and combustion systems tailored for controlled chemical processing.

Cosmetics & Personal Care:

- Thermal sterilization of creams, lotions, and personal care products to ensure safety, stability, and regulatory compliance.

- Heating and sterilization via thermal oil systems, steam boilers, reactors, tanks, and combustion systems.

Packaging & Materials Sterilization:

- Sterilization of medical packaging, sterile barrier systems, and high-integrity packaging materials using steam, thermal oil, and combustion-based heating.

Uncompromising Safety & Intelligent Control

Every thermal treatment system we supply is engineered with a “safety-first” philosophy and state-of-the-art automation:

- AS4024 Compliant Safety: Advanced electro-mechanical safety interlocks prevent unsafe operation.

- Advanced Control Systems: Modern PLC & HMI interfaces with full data logging come standard.

- Optional SCADA Integration: For advanced facilities, detailed mimics, “forever” data logging, and seamless IT/OT integration are available.

- Validation & Compliance: Commissioning trials and validation reports provided for regulatory submission.

Complete, Turnkey Thermal Treatment Packages

Our standard systems typically include:

- Thermal treatment vessel or furnace with manual or automated loading.

- Steam boilers, thermal oil heating systems, reactors, process tanks, and combustion systems integrated for complete thermal solutions.

- Complete instrumentation, valve trains, and safety systems.

- PLC/HMI-based control system with optional SCADA integration.

- Loading/unloading carts, conveyors, or automated handling systems.

- Full national service and support for installation, commissioning, and maintenance.

National Service & Support

Headquartered in Australia, Xenon Engineering provides design, installation, and commissioning services nationwide, supporting projects across:

- New South Wales: Sydney

- Victoria: Melbourne

- Queensland: Brisbane

- Western Australia: Perth

- South Australia: Adelaide

- Tasmania: Hobart

- Northern Territory: Darwin

- Australian Capital Territory: Canberra

Competitive Fixed-Price Engineering

We understand that budget certainty is vital for large-scale projects. Our pricing for thermal treatment systems is highly competitive, with fixed-price options available based on your project scope.

Contact us today for a technical consultation and quote:

📧 Email: sales@xenonengineering.com.au

📍 Proudly Australian Owned & Operated